Business

Solution For the Earth DYC

Solution For the Earth DYC

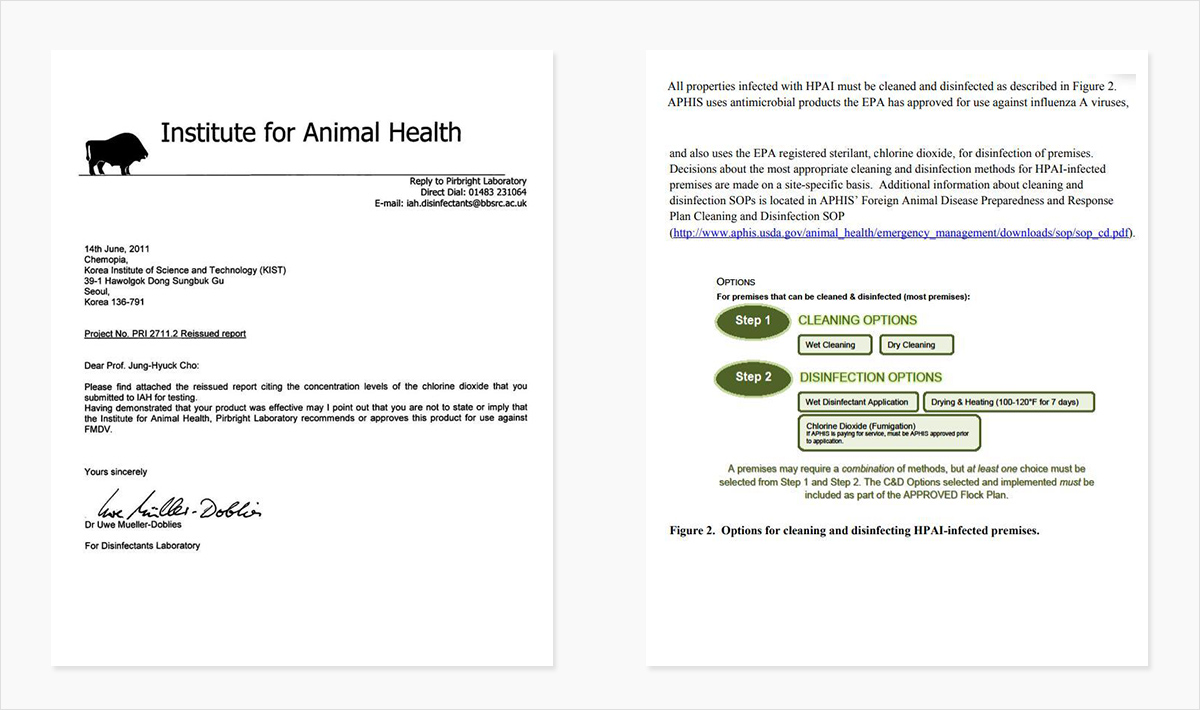

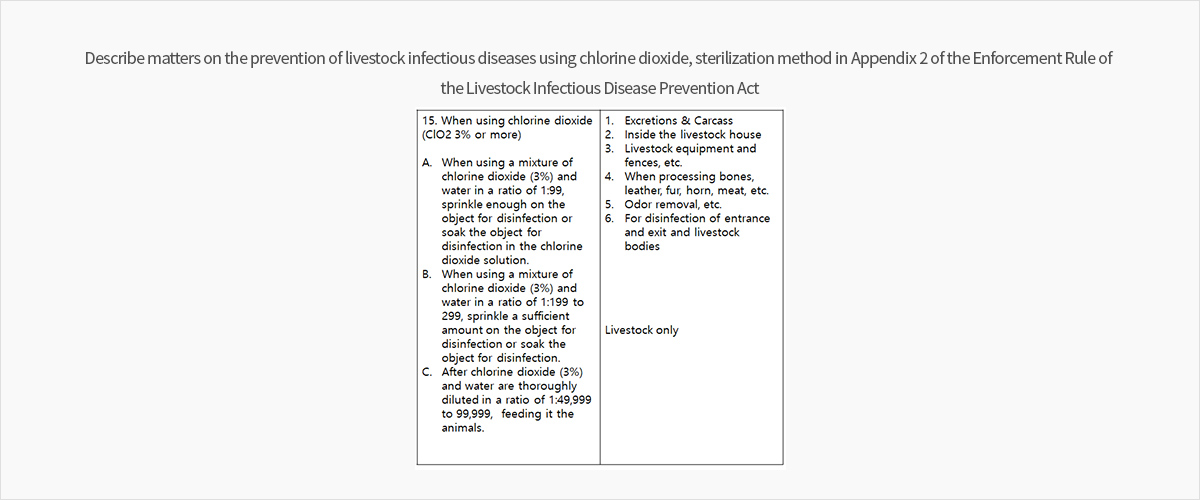

Chlorine dioxide cannot be used as a treatment for the infectious disease, but it can be used as a disinfectant for prevention spreading

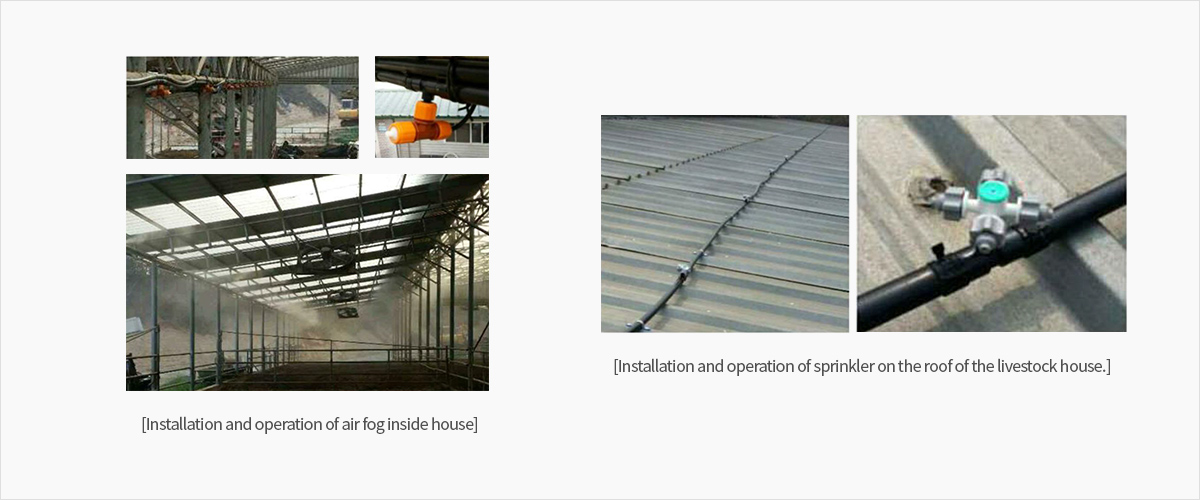

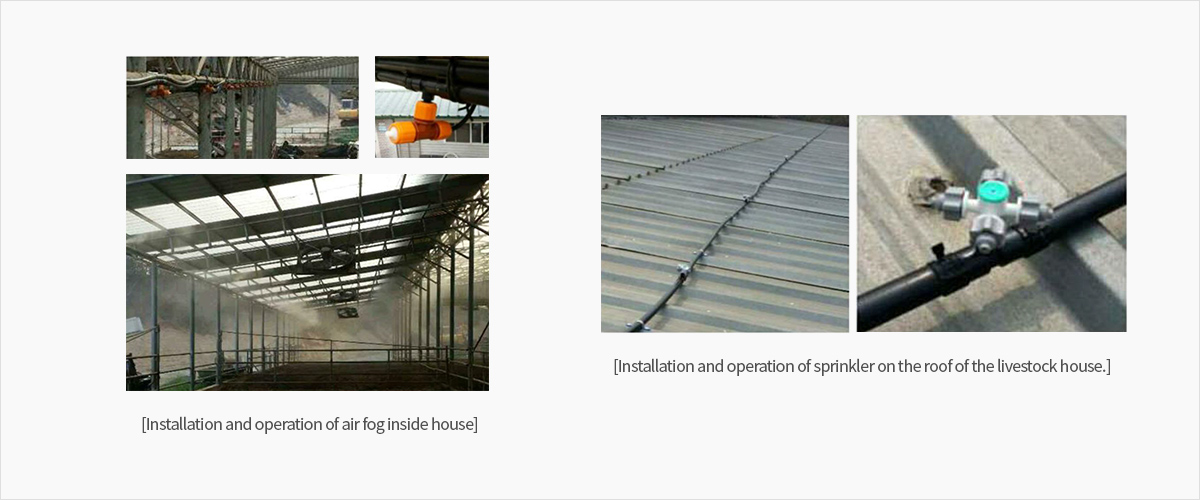

Depending on the water-soluble disinfectant, it has the advantage that it can be applied in various ways depending on the application, such as misting method, sprinkler method, or high pressure spraying.

It has the advantage of not having to use separate chemicals for disinfection and deodorization as it simultaneously reduces odor, which is a chronic problem of livestock houses.

| 1. Cooling | |

|---|---|

| Principle | feature |

|

|

| 2. Temperature drop in the livestock house | |

|---|---|

| Heat stress in domestic animal | Air fog effect |

|

|

| 3. humidification | |

|---|---|

| Principle | feature |

|

|

| 4. Reduction of odor in livestock and compost facilities | |

|---|---|

| Status of odor in the livestock house | Air fog effect |

|

|

| 5. Using of quarantine prevention products in the livestock house | |

|---|---|

| Using of quarantine prevention products in the livestock house | Air fog effect |

|

|

| 6. Reduction of dust in the livestock house | |

|---|---|

| Dust status inside the livestock house | Air fog effect |

|

|